Multiplexed NIR spectrometer technology

NIR identification in sorting processes

KUSTA1.9MPL-24V - Multiplexed NIR spectrometer for recycling

Material identification in sorting plants

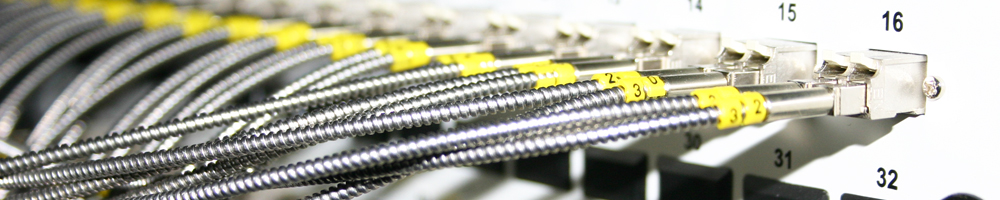

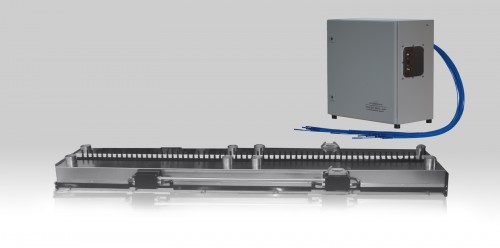

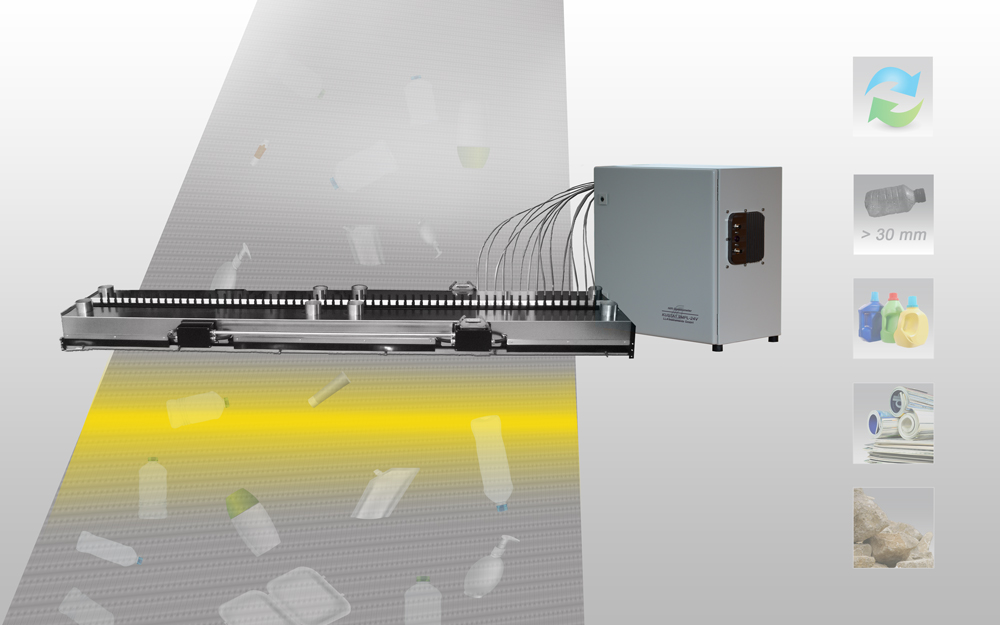

Multiplexed NIR spectrometer KUSTA1.9MPL-24V(formerly KUSTA1.9MPL) is a fast scanning near-infrared sensor, which is used for the identification of bulk solids in sorting plants. On a conveyor belt the singulated material is passed by under the illumination unit and the reflected radiation is transferred to the optical multiplexer via fiber cables. The multiplexed spectrometer scans the 64 measuring tracks at frequencies of up to 70 Hz and sends the identification results to the process control via an ethernet protocol.

KUSTA1.9MPL-24V is mainly used in plastic- and waste paper recycling. Depending on the application certain standard identification routines are included, which enable to reject several material types referring to freely selectable criteria.

In the version “-24V”, which is available from January 2016, the optical multiplexer, the spectrometer and the RGB sensor come in a separate housing of protection degree IP65, which can be mounted directly at the probe. Due to the high scan rate, materials on even 2 to 3 m wide conveyor belts can be identified at speeds of up to 3 m/s. For the detection of smaller particles (< 30 mm in diameter) hyperspectral imaging cameras KUSTAx.xMSI are recommended.

Additional equipment is described below.

Suitable software for LLA NIR technology is described here.

Schematic illustration of a sorting plant based on KUSTA1.9MPL-24V

Technical specification KUSTA1.9MPL-24V

| KUSTA1.9MPL-24V | ||

| Method |

Non-contact and non-destructive testing (NDT) method based on NIR spectroscopy; Detection of absolute remission as a function of the wavelength |

|

| Wavelength range | 1.36 µm - 1.94 µm | |

| Spectral resolution | < 8 nm | |

| Dispersion per pixel | 4 nm | |

| Scan rate | 30 Hz - 70 Hz | |

| Number of measurement tracks | Max. 64 | |

| 16bit RGB sensor | Integrated | |

| Operating voltage optical unit | 24V DC, max. 3,6A (without industrial PC and control cabinet heating) | |

| Operating voltage industrial PC | 24V DC, max. 4,8 A | |

| Operating voltage control cabinet heating | 24V DC, 7A, 150W | |

|

Voltage 24V power supply |

90…265 V AC, 50-60 Hz, fuse 20 A (T) Input: 100 V ... 240 V AC; Output: 24V DC / 20A |

|

| Environmental operating temperature | +5 °C to +55 °C | |

| Environmental operating humidity |

In process: 5 % - 95 % 20 % - 95 % rel. |

|

| Weight | 31 kg | |

| Dimensions (LxWxH) | 500 mm x 500 mm x 300 mm | |

| Base device | Optic module containing the spectrometer, optical multiplexer and control electronics in a housing of protection class IP65, external: industrial PC, 24V power adapter | |

| PC configuration | Operating system Windows® 7 Embedded, 1,7 GHz, 8 GByte RAM, Solid State Disk 80 GByte, conectivity: DVI, COM, USB, Ethernet | |

| Software |

Control software KustaMPL, customer specific analysis routines Optional: spectrometric development environment KustaSpec |

|

| Operation | Process mode: the process unit interacts via Ethernet interface with the industrial PC, which evaluates the spectra. Controling the system with a TFT display, mouse and keyboard for service purposes is possible but is not included in the scope of delivery. | |

| Probe lines | PMAmpl (Remission) or PMT (Transmission) | |

| Scope of delivery | Multiplexed NIR spectrometer KUSTAx.xMPL-24V, industrial-PC, 24V power supply | |